Background:

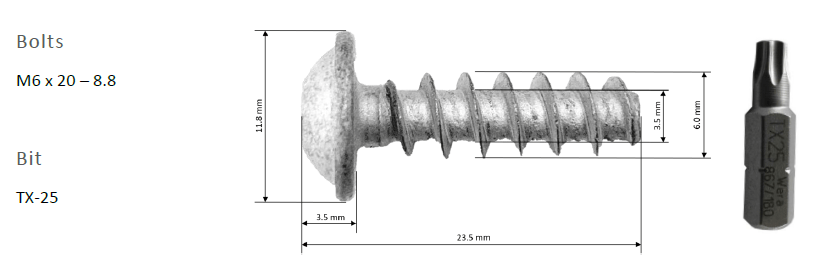

Robots are commonly used to automate routine tasks in a factory environment. A UR-5 Robot Arm, equipped with a power screwdriver, is used to drive screws at various locations within an automotive component. A bin full of screws are available, but they need to be picked up, properly oriented and fed to the power screwdriver in order to truly automate the screw driving process. The screw bit on the screwdriver is magnetic.

Problem Statement:

Enable a UR5 to pick up only one screw at a time that can be used to fasten parts. Screws will be placed in a bulk container to start. More UR5 details are listed here.

Design Constraints:

- Screws must be picked up from a separate apparatus due to space limitations.

- Screw feeders directly on the robot are not allowed. There must be a degree of separation between the end effector of the UR5 and the starting area.

- A default end effector to hold the drill will be provided, but teams are welcome to design and build their own.

- The orientation of the picked-up screw must match the orientation of the screw bit.

- Screws must be placed in an assigned location in a premade jig.

- Teams are not expected to run the driver and physically screw the screw in a workpiece.

- Consistency and reliability are the most important factors.

- There will be three total two-minute rounds per team, with time in between each round to adjust the device as needed.

- The sum of your top two rounds will be your team’s total score

Competition Area:

- The competition arena will comprise of specific zones as follows (more details to follow):

- A starting table/area where the bulk container with screws will be kept.

- An area for the UR5 robot arm.

- A table with the jig to place the screws. A hole placed on the jig will have a stronger magnet than the drill bit to take the screws from the drill bit.

Scoring Criteria:

| Identifier | Objectives | Point Totals and Rules |

|---|---|---|

| A | Sift | 10 points per screw picked up in the correct orientation |

| B | Screw | 10 points per screw released into the magnetic jig hole at the correct location |

| C | Speed |

Teams will have a maximum of two minutes to place 15 screws into the provided jig. Any time left is an additional 1 point per second saved. |

| D | No dropped screws |

5% Penalty on total points per screw dropped or placed incorrectly into the jig. Attempting to pick up a screw and missing or any screws that fall outside the starting area and not placed in jig counts as a dropped screw |

Total Points = ( ΣA + ΣB + ΣC ) * (100% – ΣD)

Images: